SwissX B100: The Ideal Solution for Maritime Decarbonization

SwissX B100 biodiesel is a cutting-edge, renewable fuel designed to help ships meet the EU FuelEU Maritime Regulation. Produced from sargassum seaweed, SwissX B100 reduces greenhouse gas (GHG) emissions by up to 93%, far exceeding the 2% reduction target for 2025 and supporting ambitious decarbonization goals.

Why SwissX B100?

- Regulatory Compliance: Fully aligned with EU GHG intensity reduction targets and ISO 8217:2024 specifications.

- Carbon Neutral: Net-zero lifecycle emissions validated by KPMG and BDO audits.

- Cost Efficiency: Reduces reliance on EU ETS allowances and qualifies for tax deductions.

- Sustainability Certified: Meets ISCC standards, ensuring traceability and environmental integrity.

Performance and Availability

- Engine Compatible: Works seamlessly with existing systems, offering a clean burn with zero operational compromises.

- Strategic Supply: Available at key ports, including Antigua and Barbuda, with a robust production reserve.

Economic and Environmental Impact

SwissX B100 helps shipping companies meet GHG reduction goals while unlocking benefits like carbon credits through the SwissX Green Token System.

Choose SwissX B100

SwissX B100 is the future of maritime fuel, combining sustainability, compliance, and performance. Make the switch today to lead the way in maritime decarbonization.

Contact: investors@swissx.com

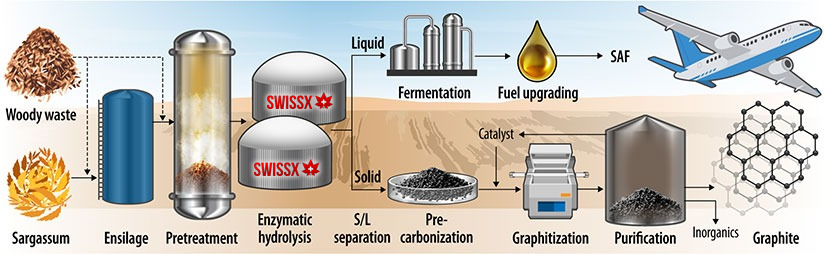

Creating SwissX Bio Diesel from Sargassum or any other useful natural raw material involves a multi-step process that transforms the seaweed’s organic materials into a sustainable fuel alternative. Here’s a detailed breakdown of each stage

- Algae: Various types of algae, such as microalgae and macroalgae, are rich in oils and can serve as excellent feedstock for biofuel production. Algae cultivation can be tailored to specific environments, including ponds, bioreactors, or open water systems.

- Waste Cooking Oil: Recycled waste cooking oil from restaurants, households, and food processing facilities can be utilized as a feedstock for biofuel production. This reduces waste and provides an additional source of raw material for biodiesel manufacturing.

- Animal Fat: Rendered animal fats, such as tallow and lard, contain triglycerides that can be converted into biodiesel through transesterification processes. Utilizing animal fats as feedstock diversifies the raw material base for biofuel production.

- Plant Oils: Various plant oils, including soybean oil, canola oil, palm oil, and sunflower oil, are commonly used as feedstock for biodiesel production. These oils contain high levels of triglycerides, which can be converted into biodiesel through chemical processes.

- Waste Grease: Grease and fats derived from food processing industries, restaurants, and other sources can be repurposed as feedstock for biodiesel production. Recycling waste grease reduces environmental pollution and contributes to sustainable fuel production.

SwissX Bio Diesel Production Process

- Harvesting: Sargassum, which floats on the ocean’s surface, is gathered from expansive areas of the sea. This step requires efficient collection methods to cover large regions effectively.

- Drying: Once harvested, the seaweed undergoes drying to reduce its moisture content. Solar drying techniques or other methods may be employed to achieve this.

- Preparation: The dried sargassum is processed into smaller pieces through grinding or shredding. This increases its surface area, facilitating subsequent treatment.

- Pretreatment: The shredded sargassum undergoes pretreatment to break down its cellulose and hemicellulose into simpler sugars. Hydrolysis or enzymatic treatment can be utilized for this purpose.

- Fermentation: Microorganisms like yeast or bacteria ferment the sugars obtained from pretreatment, converting them into ethanol or other alcohol-based fuels.

- Distillation: The fermented mixture undergoes distillation to separate the alcohol from the remaining components of the fermentation broth, yielding a crude alcohol product.

- Conversion to Diesel: The crude alcohol product is further processed through techniques like esterification or hydrodeoxygenation. These methods remove oxygen from the alcohol molecules and modify their chemical structure to closely resemble conventional diesel fuel.

- Refining: The diesel fuel produced from sargassum may undergo additional refining processes to enhance its quality and eliminate impurities.

Using a diverse range of feedstock types for SwissX Bio Diesel production offers several advantages:

- Resource Efficiency: By utilizing various feedstock sources, the production process can take advantage of underutilized resources, including waste cooking oil, algae, and animal fats. This promotes resource efficiency and reduces reliance on single-source feedstocks, minimizing the risk of supply chain disruptions.

- Waste Reduction: Incorporating waste materials such as waste cooking oil and waste grease into biodiesel production helps reduce waste disposal and environmental pollution. Repurposing these materials as feedstock adds value to otherwise discarded resources, contributing to a circular economy model.

- Environmental Benefits: Biofuels derived from diverse feedstock types typically have lower greenhouse gas emissions compared to fossil fuels, leading to reduced carbon footprint and mitigating climate change. Additionally, biodiesel produced from sustainable feedstock sources helps preserve biodiversity and ecosystems by minimizing habitat destruction associated with conventional fuel extraction.

- Energy Security: Diversifying feedstock sources enhances energy security by reducing dependence on imported fossil fuels. Locally sourced feedstocks, such as waste cooking oil and algae, can be cultivated or collected domestically, decreasing reliance on foreign oil imports and improving energy independence.

- Economic Opportunities: Biofuel production from various feedstock types can stimulate economic growth and create employment opportunities in sectors such as agriculture, waste management, and bioenergy. Additionally, developing a diverse biofuel industry supports innovation and technological advancements, fostering a sustainable and competitive bioeconomy.

- Flexibility and Scalability: The use of multiple feedstock types provides flexibility in production, allowing for adaptation to changing market conditions, feedstock availability, and technological advancements. This flexibility enhances the scalability of biofuel production, enabling expansion to meet growing demand while maintaining sustainability and cost-effectiveness.

Utilizing a diverse range of feedstock types for SwissX Bio Diesel production offers numerous advantages, including resource efficiency, waste reduction, environmental benefits, energy security, economic opportunities, and flexibility. By harnessing the potential of various feedstock sources, biofuel production can contribute to a more sustainable and resilient energy future.